Pressure Relief Valves Can Only Be Installed in Parallel

A valve installed in any position other than vertical might not perform correctly. A low pressure control.

Parts Of Gate Valve Plus Functions Of Gate Valves Helpful Guide Gate Valve Valve Piping And Instrumentation Diagram

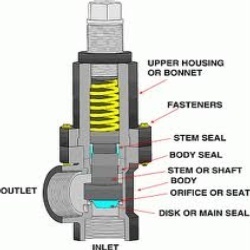

A pressure relief device designed to actuate on.

. The pressure relief valve in the system is used for safety protection only. The pressure set value must be higher than the test range but it does not exceed the allowable. Periodic Maintenance A relief valve installed in a system that.

Use a two-step reduction wheneverRead more. To help bring this system to an acceptable level pressure relief valves can be installed to help avoid unexpected pressure changes in the heating circuits. As demand increases the second valve opens.

Every refrigerating system must be protected by which of the following. When installing more than one pressure relief valves must be installed. Relief Valves in Parallel Author.

One valve opens first and handles part of the demand. A ______ must protect all air conditioning and refrigeration systems. A properly located stop valve.

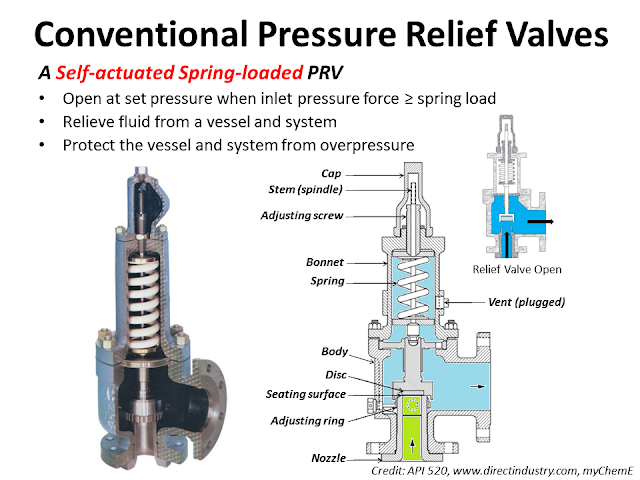

It is my understanding that valves can be designed with the same set pressure as long as the above points are reviewed even if inlet lines are not symmetrical. General Two pressure-reducing valves in series are generally used when the total reduction in pressure is greater than that attainable with one valve. This is known as pressure build-up over setpoint or simply build-up.

25 Pressure relief valves can only be installed. When control valves are installed in parallel they are set up for split range so they dont fight each other. Pressure control valve a regulator.

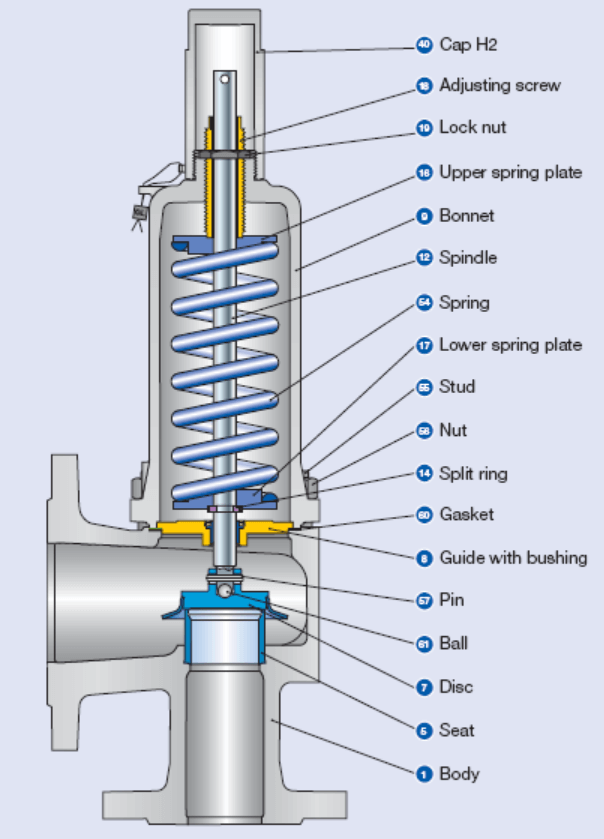

Mount PRVs in a vertical position which means upright and with the spindle vertical. Relief Valve This device is typically used for liquid service. A properly located stop valve.

The use of a rupture disc as primary relief is attractive if the relieving fluids are non-toxic non-hazardous and the system stop and the loss of fluids is not an issue. That said pressure relief valves can and do fail and its important to be able to recognize the signs in order to quickly solve the problem and keep your facility safe. They are manufactured in a variety of materials with various coatings for corrosion resistance.

A low pressure control. Parallel prv relief valve safety Created Date. The device includes a rupture disk and a disk holder.

It operates automatically by opening farther as the pressure increases beyond the initial opening pressure and recloses when the pressure drops below the opening pressure. Improperly installed valves can both cause leakage and pose safety risks. A pressure relief device.

A technician should look for ______ when first inspecting a leaking system system with a hermetically sealed compressor. Assume its designed for 600kghr steam flow rate. Please note that it is usually acceptable to have 5 of maldistribution on equipment in parallel and with 3 set pressure loss this should not be a big difference.

Volume 3 Issue 1 March 2016 Application Reduce a steady or varying high inlet pressure to a constant adjustable low delivery pressure. The same should apply to parallel relief. Pressure Build-up A relief valve has a setpoint at which it begins to open.

In parallel Decks in I9 Class 4. All ports open. Here are 3 signs of pressure relief valve failure to watch out for.

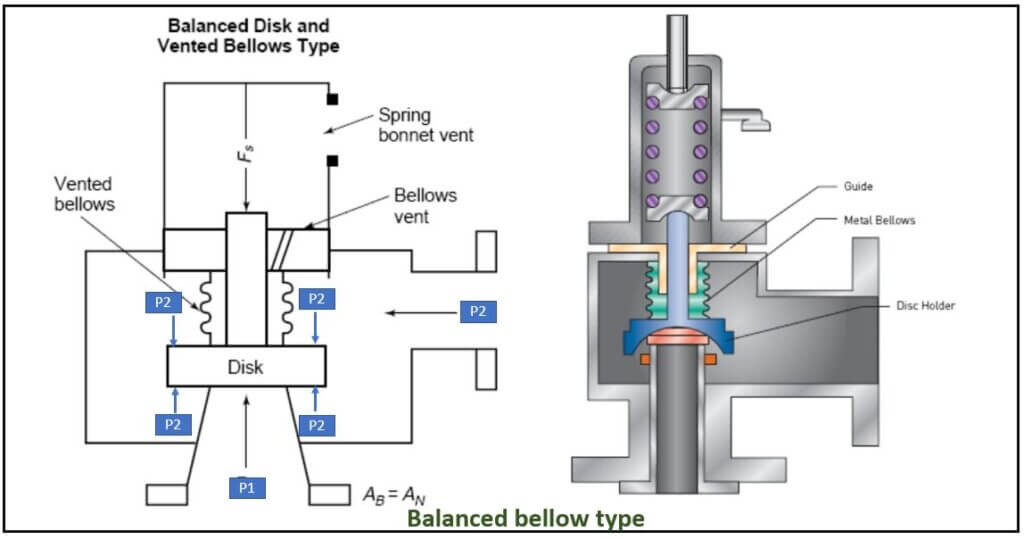

When the relieving fluids may impede the proper operation of the pressure relief valve. Especially in the initial stage because the required flow rate is very small it is often below 01 Lmin. Assume its designed for 300kghr steam.

The valve seats can freeze. Pressure relief valve installation MOUNTING. 2nd device cannot be higher than 105 of.

James R Lawrence Sr. Pressure relief valves can only be installed a in series b in parallel c vertically d horizontally b in parallel 21 what is the best use for testing with soap bubbles a to pinpoint refrigerant leaks b to find refrigerant leaks in coil fin area c to detect leaks in water tube condensers. Please note second valve was added to add extra layer of protection for a higher flow rate in case of rarely possible worst case scenario assuming first one does not lift.

After all the liquid has been removed from an average 350 ton approximately how much vapor refrigerant remains in the system. In the case of over-pressurization if the pressure safety valve fails to operate or unable to relieve excess pressure fast enough the rupture disc will come into action and burst controlling the pressure. 2 15 relief valve set pressure 8barg.

Safety Relief Valve This device includes the operating characteristics of both a safety valve and a relief valve and may be used in either. Systems with sensitive equipment Similarly in pneumatic systems with multiple components excessive pressure may damage equipment albeit most of the time without safety-relevant issues. This is especially crucial for cast iron valves.

For flanged valves be sure to draw the bolts down evenly. The rupture disk may be used alone in parallel with or in conjunction with pressure-relief valves. The seat tightness operation and set pressure of the valve may be affected.

Dual pressure-relief valves shall be installed with a three-way valve to allow testing or repair 71332 Pressure-relief valves discharging into the low side of the system Under the conditions permitted in Clause 7362 a single relief valve not rupture members of the required telerding capacity may be used on vessels with an internal gross volume of 028 m 10 ft or more. A pressure relief device. A safety valve mounted in a non-vertical orientation may not perform as expected.

A refrigerant receiver A. To guarantee that your valves are installed correctly and prevent damage to both the valve and the system. A pressure relief device.

Only one need be set at or below MAWP. -pressure relief device -gauge manifold -service king valve -all of the above. Heres the rule of thumb.

For the valve to fully open and pass the maximum flow pressure must build up to some level above the setpoint of the relief valve. Rupture disc installed parallel to the pressure safety valve. Using multiple speed control valves in parallel or bypass throttle valve can take in to consideration.

Pressure relief valves can only be installed. A relief valve PSVPRV can still be installed in parallel to protect against other relieving scenarios. The rupture disk is designed to burst at set inlet pressure.

Rupture disc installed below the pressure safety valve. 1 1 relief valve set pressure 7barg.

What Is A Pressure Relief Valve Instrumentation And Control Engineering

What Is Prv Pop Test Popping Test Amarine

Pressure Relief Valve And Pressure Safety Valve Types And Working The Piping Talk

Pressure Relief Valve And Pressure Safety Valve Types And Working The Piping Talk

Pressure Relief Valves How They Work Tameson Com

What Is A Pressure Relief Valve Instrumentation And Control Engineering

Hydraulic Power Systems Valves Part Three

Swing Check Valves Valve Water Valves Fire Suppression

Flyer Starsteam Pressure Relief Valve Weir Power Industrial Pdf Catalogs Technical Documentation Brochure

Asme Pressure Relief Valve Testing Validyne Engineering

Pressure Relief Valves Types And Working Principle Youtube

Conventional Pressure Relief Valve Component Intro Amarine

Pressure Relief Valves Empowering Pumps And Equipment

Inako Pratama Supplies Product Valve Instrumentation Flange Fitting Stariner Control System

Spring Loaded Psv Model A Spring Loaded Pressure Safety Valve Is A Download Scientific Diagram

An Introduction To Relief And Safety Valves Safety Valve Relief Valve Hydraulic Systems

Deluge Valve Operation Using Solenoid Valve Animation Fire Protection System Deluge Hydraulic Systems

What Is A Pressure Relief Valve Instrumentation And Control Engineering

Comments

Post a Comment